Since 2013 source factory

Brewery Equipment Manufacturers

- Competitive price with high quality

- From nano to large craft beer brewing equipment

- Custom design tailored to brewers' unique brewing requirements

Since 2013 source factory

Brewery Equipment Manufacturers

- Competitive price with high quality

- From nano to large craft beer brewing equipment

- Custom design tailored to brewers' unique brewing requirements

Meto have been exported more than 95 countries and region as Europe, Asia, America ,Oceania and Affrica.

Trusted by 1,500+ craft breweries for top-tier equipment & services – loved by brewers

With a 20,000㎡ workshop and automated manufacturing equipment, we deliver precision-engineered brewing systems at scale

Our Products

We have over 30 models for you to choose from. If you need help to select suitable brewing equipment for your brewery, we are always here to support you. Meto is the most trusted place to purchase the brewery equipment for beginners and professionals in 2025

- Wort/Brew: 1HL-2HL (BBL)

- Batch/Day: 1-2

- Brewhouse: 2 vessels

- Heating Method: Electric / Steam

- Brewery Area: >10M²

- Wort/Brew: 3HL-10HL (BBL)

- Batch/Day: 1-3

- Brewhouse: 2/3 vessels

- Heating Method: Electric / Steam

- Brewery Area: >25M²

- Wort / Brew: 10HL-20HL (BBL)

- Bach / Day: 2-4

- Brewhouse: 3/4/5 vessels

- Heating Method: Steam

- Brewery Area: >100M²

- Wort / Brew: 20HL-100HL (BBL)

- Bach / Day: 4-8

- Brewhouse: 4/5/6 vessels

- Heating Method: Steam

- Brewery Area: >500M²

- Capacity: 1HL-300HL (BBL)

- Style: Vertical / Horizontal / Stacked

- Working Pressure: 2-3Bar

- Cooling Jacket: Dimple jacket

- Insulation: Polyurethane

- Cooling system

- Cleaning system

- Milling System

- Keg Filler & Washer

- Can & Bottle Filling machine, etc.

Our Partners

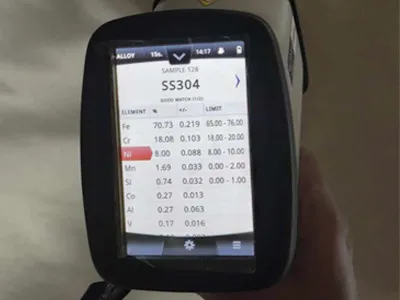

The whole line of products is made of SUS304 stainless steel raw materials and accessories, and the key components and auxiliary equipment are selected from international or Chinese well-known brands to ensure excellent quality and durability from the source.

Customized Your Brewery

Custom Brewery Equipment Suits Your Projects

- Customized brewhouse system, support Decoction, Infusion processes

- Compact or modular (scalable) line layouts are available

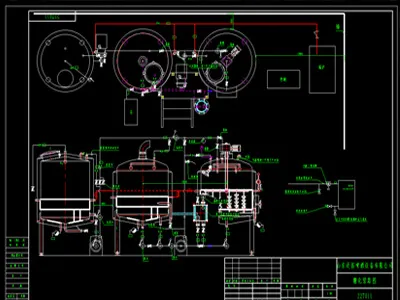

- Provide 3D model and process flow diagram

- Heating method (steam/electric/direct fire) is configured on demand

- Control system can choose manual, semi-auto and automatic

- One-stop service from design, manufacturing to installation and commissioning

Successful Cases

Meto’s brewery equipments have won the trust of many customers with high-quality products and thoughtful services. Successful cases are spread all over the world, with a good reputation and continuous cooperation

Our product Advantage

europe quality

Our reliable quality will safeguard your beer production, protect your investment, and ensure your production efficiency.

Innovative Brewing

50+ Flexible Configurations From your logo to tank size and features, can be customized according to your idea

energy conservation

Laser weld cooling and heating jacket design, heat recovery system, significantly improve the utilization efficiency of thermal energy

6 Years Warranty

Customers who purchase Meto brewery equipment can enjoy an exceptionally long 6-year warranty for the tank body, 1-year warranty for auxiliary machines and accessories

Modular design

Reduced 70% expansion costs and avoidance of duplicate investments. Easy to dismantle, saving installation and maintenance costs 20%

Accurate Process Control Capability

Saccharification efficiency up to 95%, batch stability up to ±0.2°P, restoring master recipe accuracy

Authoritative certification

CE-PED / ASME / TUV / SGS / UL / CSA Meets pressure vessel and international food safety approvals

Exquisite appearance & fine polishing

International trend appearance design, brewhouse out shell overall polished. Tank inner liner polishing roughness ≤ 0.4μm, eliminating hygiene blind spots

Strict Quality Control

9 major stages, 125 standardized quality inspection procedures. Every set of brewery equipment must pass our rigorous full process quality inspection system before being delivered to global customers

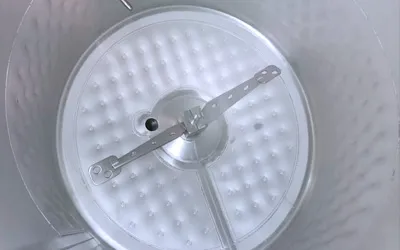

Raw material inspection

100% of the metal element content is detected by an imported spectrometer, the nickel content is not less than 8%, the chromium content is not less than 18%, the welding wire is made of stainless steel 316 material, and the ultrasonic thickness is detected

Drawing review

Prior to equipment manufacturing, we perform a triple professional review process of technical compliance, production feasibility and customer confirmation to ensure that the design fully meets process and safety requirements

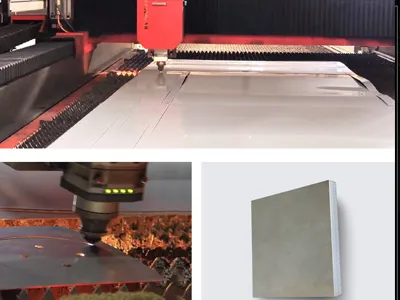

cutting inspection

The laser cutting machine is used to cut the material to ensure that the processing accuracy of all metal plates and pipes meets the design requirements, and to ensure the product assembly quality and neat and beautiful appearance

Sheet metal inspection

Inspect the quality of all workpieces of the products in the blanking process, including the blanking size, edge burr, surface quality, weld quality, etc

welding inspection

The weld is guaranteed to be uniform and consistent, without slag inclusion, weld penetration, deformation and other defects. The residual height is 0-1.5mm, NDT test as request.

Assembly inspection

The cylinder is neatly docked with the head and the lower cone, the orientation and size of the nozzle meet the requirements of the drawing, and the surface is not scratched

Polishing inspection

The polishing texture is uniform and consistent, and the inner tank is detected by a roughness detector to ensure that the Ra ≤0.4μm, and the outer weld is sand-polished

Pressure Test

The tank and jacket are tested for hydropressure, and the fermenter is tested three times, the test pressure of the inner tank is 2 bar, steam jacket is 4 bar, and the test time >24 hours

Final assembly & test

The brewhouse is assembled and energized to test the mixing, pumping, piping, cleaning and control systems. Support customers to inspect goods remotely or witness on-site

About Meto

Shandong Meto Beer Equipment Co., Ltd is an international craft brewing equipment manufacturing company. Our company integrates design, research and development, pro-duction, sales, installation, and after-sales service. Our main product is beer brewery, distillery equipment ,stainless steel tanks and other turnkey services.

Meto have been exported more than 95 countries and region as Europe, Asia, America ,Oceania and Affrica.

Equipment and services for more than 1,500 craft breweries

China’s top 10 craft brewing equipment companies.

More than 30 patented technologies, national high-tech enterprise, ISO 9001, CE Ped certified, SGS & TUV certified.

Professional, enthusiastic and reliable Brewery Equipment specialists

Contact our sales engineers to discuss their needs. Our staff can answer all of your design and engineering questions, as well as go into detail.

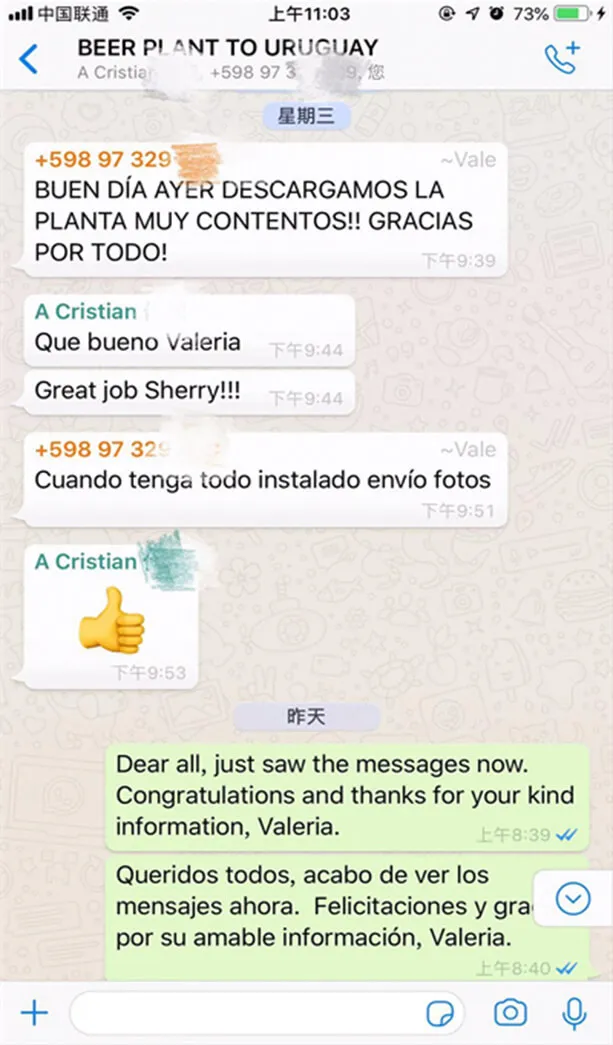

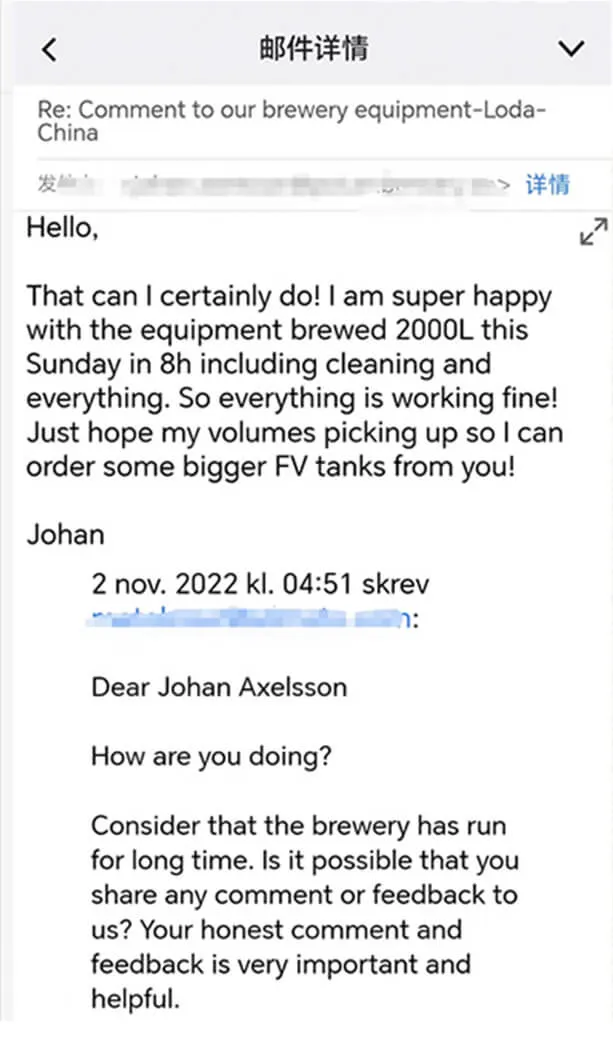

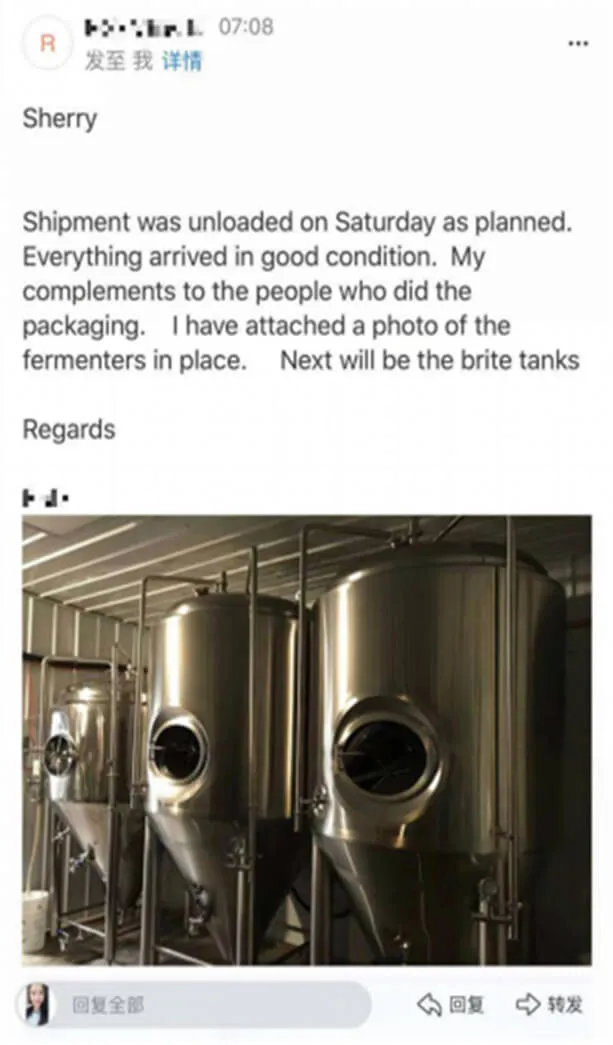

What Our Happy Clients Say

Don’t just take our word for it. Find out what satisfied customers have to say about our high quality, competitively priced brewery equipment. Read their reviews to find out why our products are the best choice.

Need Further Help?

We are love to hear from you and discuss your project needs! Let us provide quality solutions and exceptional services for you.

Get in touch

Connect with one of our sales team now – 24/7 availability. Kindly check our brewery equipment quality by yourself and you will see that you have found the right supplier.