Since 2013 source factory

custom stainless steel tank Manufacturer

- Custom-built storage and processing tanks for every industry

- Competitive price with high quality

- CE-PED / ASME / TUV / SGS / ISO9001 certification

- Laser welding jacket, inner polishing precision ≤0.4μm

- OEM/ODM,Custom-built tanks sizes from 50L to 200KL+

Meto have been exported more than 95 countries and region as Europe, Asia, America ,Oceania and Affrica.

Trusted by 3,000+ projects for top-tier equipment & services – loved by customers

Full OEM/ODM support from prototyping to mass production, with flexible customization and strict quality control.

Our Stainless Steel Tank Solutions

We specialize in the production of functional stainless steel tanks and vessels equipment. Our tanks can serve multiple purposes, from plain storage to fermentation and mixing.Whether you need a small 100-liter vessel or a custom-built stainless steel tank with a capacity of up to 200 m³, we offer tailor-made storage and process tanks that meet the highest industry standards.

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric

- Wall Thickness: 2mm – 10mm

- Volume/Capacity: 100L – 300KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 300KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low Pressure

- Wall Thickness: 2mm – 12mm

- Volume/Capacity: 50L – 200KL (customizable)

- Material: SUS304 / SUS316L(or request)

- Pressure: Atmospheric / Low / High Pressure

- Wall Thickness: 2mm – 12mm

The Industries We Served

Beer & Beverage

Wine & Spirits

Biotech & Pharmaceutical

Dairy

Food

Cosmetic & Personal Care

Oil

Water Treatment

New Energy / Battery

Not sure which tank is the best choice?

Not sure what type of stainless steel tank you need? Contact our team. We’ll help you explore the options and create a solution that fits your production goals, space, and budget. Or request a non-binding quote and see what we can do for your business.

Custom stainless steel tanks for your industry

Our tank portfolio includes a wide range of models and features. You can choose from

- Jacketed tanks for temperature control

- Horizontal or vertical tanks based on your layout

- Vacuum or pressure tanks for sensitive applications

- High-polish or matte finishes based on hygienic or visual needs

- Custom fittings such as manholes, CIP nozzles, and agitators

Strict Quality Control at Every Step

9 major stages, 125 standardized quality inspection procedures. Every set of brewery equipment must pass our rigorous full process quality inspection system before being delivered to global customers

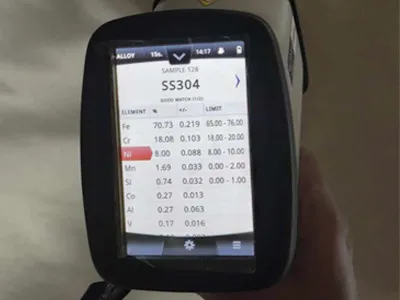

Raw material inspection

100% of the metal element content is detected by an imported spectrometer, the nickel content is not less than 8%, the chromium content is not less than 18%, the welding wire is made of stainless steel 316 material, and the ultrasonic thickness is detected

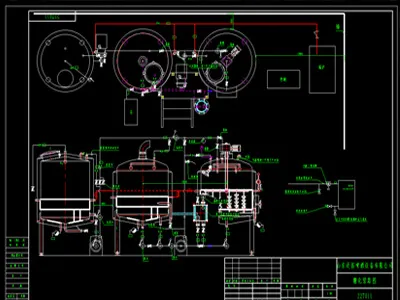

Drawing review

Prior to equipment manufacturing, we perform a triple professional review process of technical compliance, production feasibility and customer confirmation to ensure that the design fully meets process and safety requirements

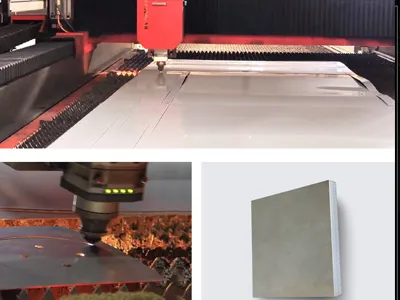

cutting inspection

The laser cutting machine is used to cut the material to ensure that the processing accuracy of all metal plates and pipes meets the design requirements, and to ensure the product assembly quality and neat and beautiful appearance

Sheet metal inspection

Inspect the quality of all workpieces of the products in the blanking process, including the blanking size, edge burr, surface quality, weld quality, etc

welding inspection

The weld is guaranteed to be uniform and consistent, without slag inclusion, weld penetration, deformation and other defects. The residual height is 0-1.5mm, NDT test as request.

Assembly inspection

The cylinder is neatly docked with the head and the lower cone, the orientation and size of the nozzle meet the requirements of the drawing, and the surface is not scratched

Polishing inspection

The polishing texture is uniform and consistent, and the inner tank is detected by a roughness detector to ensure that the Ra ≤0.4μm, and the outer weld is sand-polished

Pressure Test

The tank and jacket are tested for hydropressure, and the fermenter is tested three times, the test pressure of the inner tank is 2 bar, steam jacket is 4 bar, and the test time >24 hours

Final assembly & test

The brewhouse is assembled and energized to test the mixing, pumping, piping, cleaning and control systems. Support customers to inspect goods remotely or witness on-site

About Meto Tanks

Trusted supplier of stainless steel tanks & vessels

Meto is a professional stainless steel tanks manufacturer. Our company integrates design, research and development, pro-duction, sales, installation, and after-sales service. Our main product stainless steel tanks and other turnkey services.

With over 20 years of experience in stainless steel tank manufacturing, we have become a trusted supplier to stailess steel tanks big and small across the globe.

Over 26,000+ stainless steel tanks installed

95+ countries served

OEM & Custom Designs available

Fast delivery & worldwide logistics

Technical support + remote guidance

Whether you’re building a microbrewery or expanding capacity, we’re here to help – from planning to production to after-sales.

Why choose a stainless steel tank from Meto Tanks

Your Partner in Stainless Steel Tank Manufacturing

Every tank is built with food-grade 304/316L stainless steel, TIG welded, polished inside and out, and pressure-tested before shipment — with inspection reports provided.

We offer a 3-year extended warranty for the tank, and provide lifetime technical assistance, installation and fast local sapre parts supply.

CE, PED, ASME, TUV, SGS and ISO 9001 compliant — ready for global import and brewing regulations.

Every project is unique. We specialize in custom-built stainless steel tanks designed to meet your exact specifications—capacity, pressure, fittings, finish, and industry standards.

Trusted by 3,000+ customers in 95 Countries.We have built trust with our customers through our commitment to quality and service.

Our English-speaking sales & engineering team responds within 12 hours and supports you across time zones.

Professional, enthusiastic and reliable tanks specialists

I have 8 years of experience in the industry, which allows me to quickly understand your needs and develop the most suitable solutions for you.

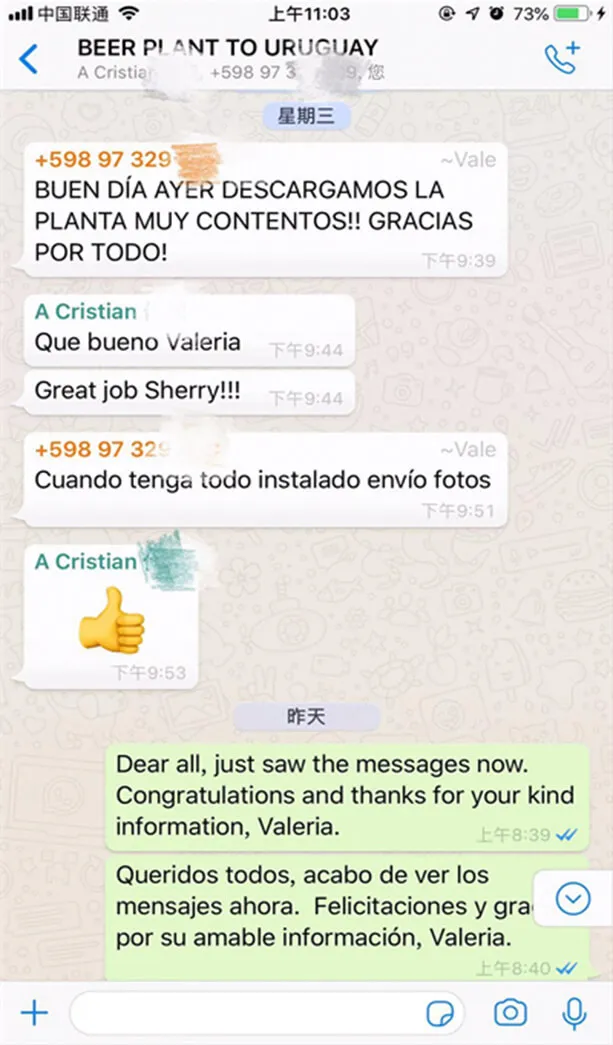

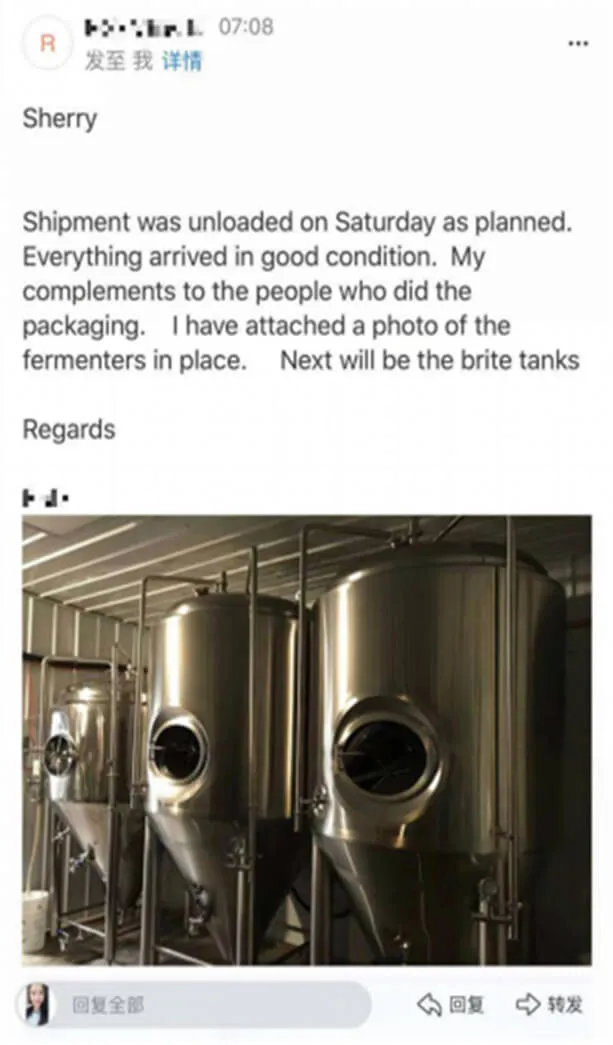

Global Projects & Testimonials

1,500+ Breweries Choose METO – From Germany to Chile. Meto’s brewery equipments have won the trust of many customers with high-quality products and thoughtful services. Successful cases are spread all over the world, with a good reputation and continuous cooperation

What Our Happy Clients Say

Don’t just take our word for it. Find out what satisfied customers have to say about our high quality, competitively priced stainless steel tanks. Read their reviews to find out why our products are the best choice.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Our standard materials include SS304 and SS316L. We can also provide other grades upon request, depending on the chemical or temperature requirements of your application.

40-60 days, depending on tans size and quantity or custom features.

There is no MOQ. We accept small orders and one-off custom tanks—perfect for pilot projects, R&D, or specialized production needs.

Yes, we ship worldwide. We also provide all necessary export documents, and our products meet certifications such as ISO, CE, PED, and ASME, as required.

Want to find professional stainless steel tanks factory to save time & cost?

Custom-Built Tanks. Factory-Direct Support.

Free drawing + technical advice from experts.

Get a Quote Now

Connect with our sales team now – 24/7 availability.

Kindly check our brewery equipment quality by yourself and you will see that you have found the right supplier.